What is Box Build Manufacturing?

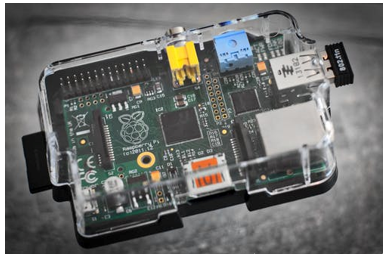

Box build manufacturing is basically the manufacturing of an entire electronics device, including the PCB, all electronics components as well as the covers and casings depending on the client’s requirements. This is opposed to sourcing out PCB design and fabrication for later assembly with separately sourced components such as chips, jacks and ports. Many companies, especially electronics startups engage in this practice of contracting other companies to create their entire products.

Unlike before, separate companies are sourced out for every component required for an electronic device. Not too many companies are able to engage in box build manufacturing, so device makers have to resort in contracting several component sources and assembly plants to complete and distribute their devices. Thanks to advances in engineering and fabrication such as 3D printing, we now have box build manufacturers that can handle the creation of entire devices.

What Are the Benefits of Box Build Manufacturing?

One great benefit in contracting a box build manufacturer, is that the process of device creation becomes so much easier for companies especially for startups. There’s no more need to form a supply chain and complicated logistics for product creation and distribution.

To be truly effective, a build box manufacturer of say, an electronics device, should be able to handle the following:

- Component creation and sourcing – have a capable and efficient supply chain for materials and proper equipment for fabrication.

- Component assembly – capable facilities and labor for assembly.

- Testing – have the proper testing facilities, equipment and personnel.

- Product configuration and software installation

- Packaging and Labelling

- Warehousing – sufficient storage for finished products for all clients.

- Order Fulfillment – ability to fulfill orders on time.

- After-market service and repair – ability to provide repair, replacement and support for finished products.

For a smooth build box development cycle, the client should provide all the necessary requirements as much as possible and provide more than just the product concept. Though a capable build box maker will still be able to pull that off but at a cost. The client’s responsibilities include:

Product Recipe

Otherwise known as the bill of materials. What materials and components should the product be made of? To be able to build a whole product, it includes the quantity of components or amounts of material to be used. Sources may come from the client or can be handled by the build box manufacturer/electronics management services (EMS) provider.

Product Dimensions

The client needs to specify what size, dimensions and how much the finished product has to weigh. Coupled with the product recipe, the EMS should be able to source out the proper materials and components. This will also affect the product’s packaging and shipping later on.

3D CAD Model

If for example, the product concept is already proven or exists. An example is a computer mouse. Then, the EMS would simply require what the product will look like inside and out plus the components required through a 3D CAD Model. This will make the building process much simpler and faster as the EMS would not have to spend much time with R&D, which will also cut the cost on the side of the client.

Prototype

A working prototype will eliminate the EMS need to spend on R&D for proof of concept. What’s left, in case the prototype isn’t the final product design, is for the EMS to improve, optimize and integrate components to create a more efficient design with or without a 3D CAD Model.

How the product should be tested

The customer needs to provide how his product needs to be tested. The manufacturer is under no obligation to torture test any product. This is unless they have given the requirement and parameters on how testing should be done. The EMS just has to make sure that the device is functional at the bare minimum.

Packaging and Shipping Info

This phase may seem optional. But, it can still be handled by a competent box build company. Often the finished product determines many factors during the manufacturing process, for examples how many items per batch, where the product is shipped and the product’s net weight.