DEFINITION:

Legitimate means ‘legal’ and Reverse Engineering means ‘the replication of another manufacturer’s goods following detailed examination of its formation or creation.’ “Reverse Engineering” is generally used in describing most common non-legitimate tactic of Intellectual property theft. However, there is a legitimate necessity for this means of engineering within an organization or company. The most obvious needs are apparent in a company that holds older technology where design records have been lost and or accidentally destroyed. This need also becomes necessary in a Merger and Acquisition scenarios where a company acquires another in a distress or in a non-cooperative circumstance and design records are not passed on properly.

In these cases and other cases a legal and legitimate need is obvious and this need can vary on the type of engineering needed and here are some of many areas of need:

REVERSE ENGINEERING:

It is also called back engineering. It is the procedure in which a human-made item is deconstructed to divulge its planning and designs. In other words, it can also define as to extricate recognition from the object. This process is related to scientific research, but the only deviation is that this research is about a real phenomenon. Back engineering is appropriate regarding chemical engineering, electronic engineering, mechanical engineering, software engineering and biological systems.

This engineering is also worn by businesses to conduct existing physical geometry into digital goods build out the environment. It uses for the making of the digital 3D logbook of their assets or to evaluate competitors’ products.

REVERSE ENGINEERING OF SOFTWARE:

In 1990, (IEEE) defined back engineering as “the procedure of scanning a subject system to recognize the system’s parts and their relationships and to design descriptions of the system in another form.” In this ‘subject system’ is the end good of software expansion. Back engineering is the procedure of inspection only. It can be conducted from any phase of the product cycle.

There are two components in back-engineering, one is designed recovery, and another is re-documentation. Design recovery is the using of cogitating or subtraction from general knowledge of the goods to discerning the goods practically. Meanwhile, re-documentation is the formation of new renditions of the computer code so that can be easily understood. It can also be seen as ‘moving backward by way of the development cycle.’

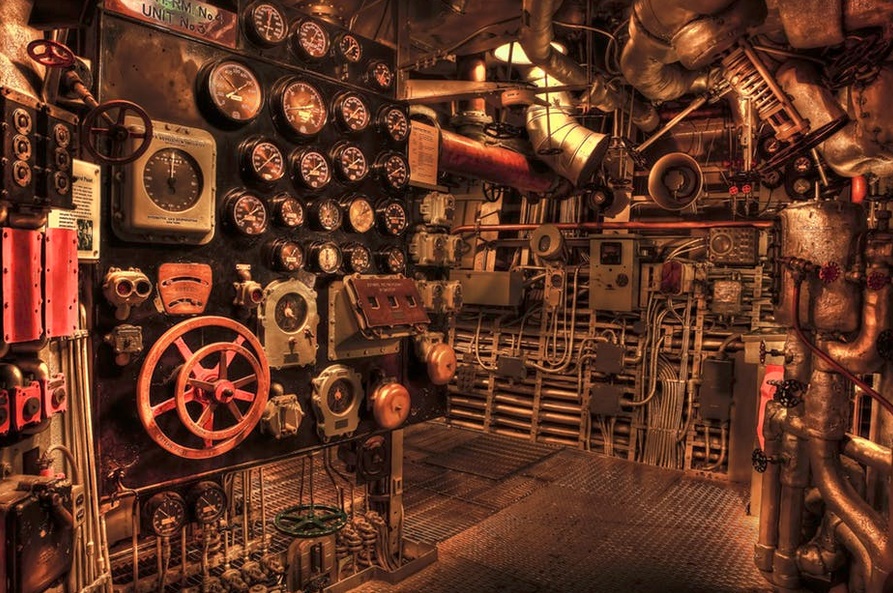

REVERSE ENGINEERING OF MACHINES:

It has become an operable method to design 3D virtual dummy of an existing physical part for operating in 3D CAE, CAD, CAM or some other software. This procedure requires measuring an item and then remodeling as a 3D dummy. A physical item can be dignified using 3D scanning technologies like laser scanners, CMMs or industrial CT scanning (computed tomography). The measured statistics can usually act as a point cloud.

Hybrid modeling has regularly used the term when parametric modeling and NURBS are performed together. They use a mixture of freedom surfaces, and geometric surfaces can supply a strong method of 3D modeling. Areas of freedom data can be united with exact geometric surfaces to assemble a hybrid model. A classic example of this would be back engineering of a cylinder head.

REVERSE ENGINEERING FOR MILITARY APPLICATIONS:

Reverse engineering is often used by people to copy other nations’ technologies, statistics or gadgets that they have been secured by regular soldiers in the paddock or for intelligence performance. Well-known examples from the Second World War and later include:

JERRY CAN: American and British forces observed that the German had gasoline cans with the superior draft. They back-engineered carbon copies of those cans. These new cans were traditionally known as ‘Jerry cans.’

PANZERSCHRECK: The Germans seized a Bazooka during Second World War and they back-engineered it to generate the larger PANZERSCHRECK.

SCR-584 RADAR: It is replicated by USSR after the WWII, known in the form a few mitigations, CLIP-584.

China has back engineered many samples of Russian and Western machinery from combatant crafter to missiles and also HMMWV cars.

TUPOLEV FU-4: In 1944, 3 American B-29 bombers in operation over Japan were requisite to land in the USSR. The Soviets didn’t have the same tactical bomber; they decided to replicate the B-29. In three years, they had flourished the Tu-4. A perfect duplicate of B-29.

There are much more military applications to be discussed.

REVERSE ENGINEERING PROTOCOLS:

Protocols are sets of regulations that narrate message formats and how messages are switched, that is protocol state-machine. Appropriately, the trouble of protocol back-engineering can be separated into two sub-problems. First is state-machine back-engineering and second is message format.

Mostly, the protocol state-machines can be lettered either by way of the process of offline training and online training. Offline training of small state-machines is familiar to be NP-complete. At the other side, online training can be finished in polynomial time. There has been a slighter effort on back-engineering of state-machines of protocols.

The message formats have traditionally been back-engineered by way of an unvaried manual procedure. This intricate analysis of how protocol execution procedure messages, but new research suggested some automatic resolutions. Typically, these automatic reaches either group perceive messages into clusters using different clustering analysis or imitate the protocol resolution tracing the message managing.

DRAWBACKS OF REVERSE ENGINEERING:

Following are the two main drawbacks of Back Engineering.

You can never really deconstruct an application fully to its native state before being composed. Additionally, it can be very hard to build anything of a deconstruct application due to the garble of the censorious and crucial source code. Essentially, they burden a ton of applicable code into the app to push off back engineers and make it even harder than it already is to execute the revocation. These two drawbacks only make the affection of successfully transposing an application all that better.

BENEFITS OF REVERSE ENGINEERING:

It expands the life of the mature hardware. By way of this, they can design a better copy of something. It requires taking an existing wedge and producing the design, statistics or other instructions and then generating an improved copy of it. It also saves cash from not having to exchange an older segment of machinery or apparatus. It is like copying reports that you don’t know off the tutee next to you in class.

Conclusion; yes reverse engineering can be and is used in intellectual property theft. However, there legal and legitimate reason to use engineering skills to reverse engineer technology that is wholly owned by a company. As mentioned above, some legitimate reasons are in the loss or destroyed original designs.

In these cases, the need for qualified engineers is a must. At Giltronics Associates, a team of engineers understand the complexity of the reverse engineering and can answer questions in the efforts to best guide their clients and customers. Contact Giltronics Associates for any Reverse Engineering questions here.